19 Jul 2023

New IEA Report: Clean Energy Technologies Driving Demand for Neodymium and Dysprosium

In July 2023, the International Energy Agency (IEA) released the inaugural edition of the Critical Minerals Market Review, along with their new online data explorer providing demand projection results under various energy scenarios and technology evolution trends.

Between 2017 and 2022, there has been a remarkable surge in mineral demand driven by the rapid rise of clean energy. The report highlights a promising outlook for energy transition minerals, although placing increasing pressure on the global mining industry.

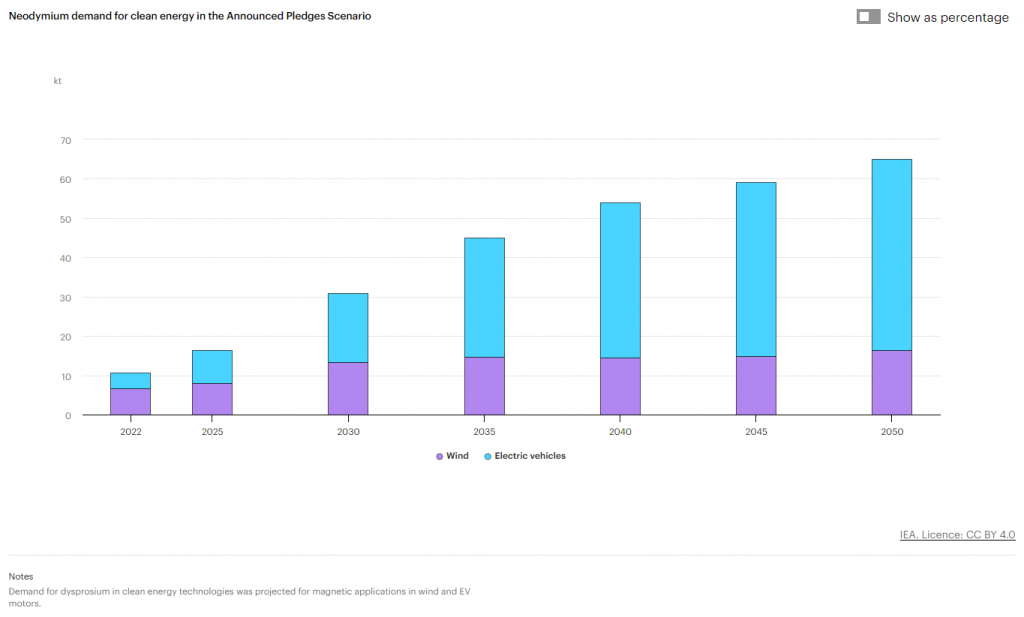

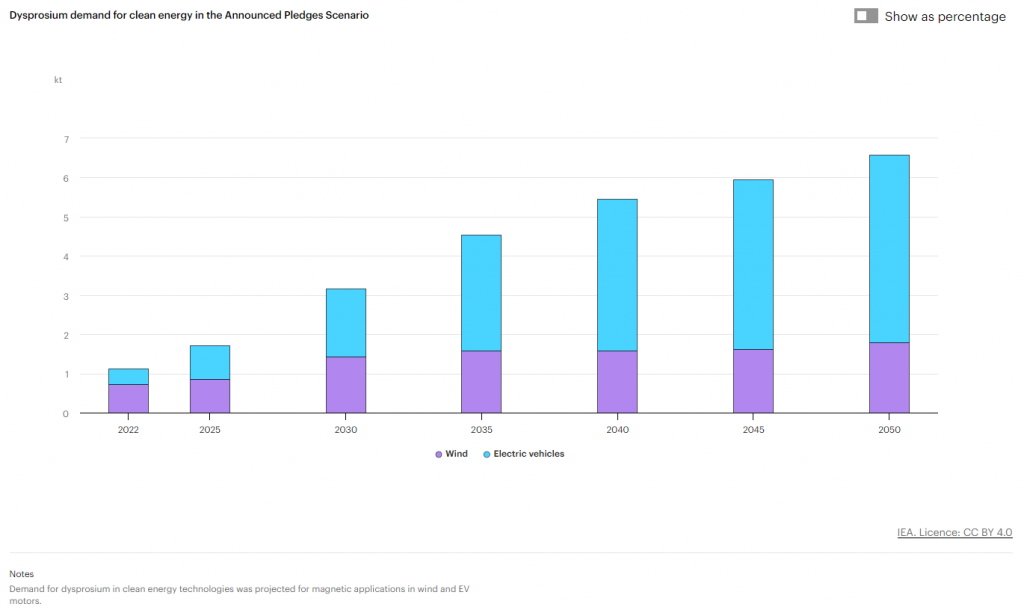

In particular, rare-earth elements such as neodymium and dysprosium are key minerals for renewable energy technologies such as wind turbines and electric motors. In fact, the demand of these minerals witnessed a 45% surge in 2022 driven by the expansion of renewable energy installations worldwide.

Rare Earth minerals demand for clean energy in the announced pledges scenario (©IEA Critical Minerals Data Explorer)

The IEA report emphasises the significance of having diverse supply sources and responsible mineral extraction practices. But how will Europe achieve this? By establishing a European recycling infrastructure to reduce reliance on third countries, ensuring better supply security and mitigating environmental impacts.

How is the REEPRODUCE project securing the European Rare-Earth Elements recycling value chain?

In this context, the goal of the REEPRODUCE project is to establish the first sustainable and complete European REEs-recycling value chain at industrial scale able to produce REEs from end-of-life products at competitive cost and with environmentally friendly technologies. This will ensure an important and strategic value chain for Europe’s green transition.

During the first year of the project, the REEPRODUCE consortium has developed the Intelligent Sorting Pilot that showcases promising progress in sensing, identifying and separating end-of-life products (e.g., mixed electrical and electronic equipment waste) containing permanent magnets such as neodymium and dysprosium. The next states of development will involve building robots capable of extracting the magnet-containing component from each item, and subsequently extracting the magnet itself.

More information: